In my previous post I described in detail how I created a ROM replacement for the Commodore Plus/4 computer and how I made sure that it would fit into the very tight space of the closed case.

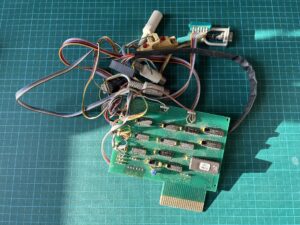

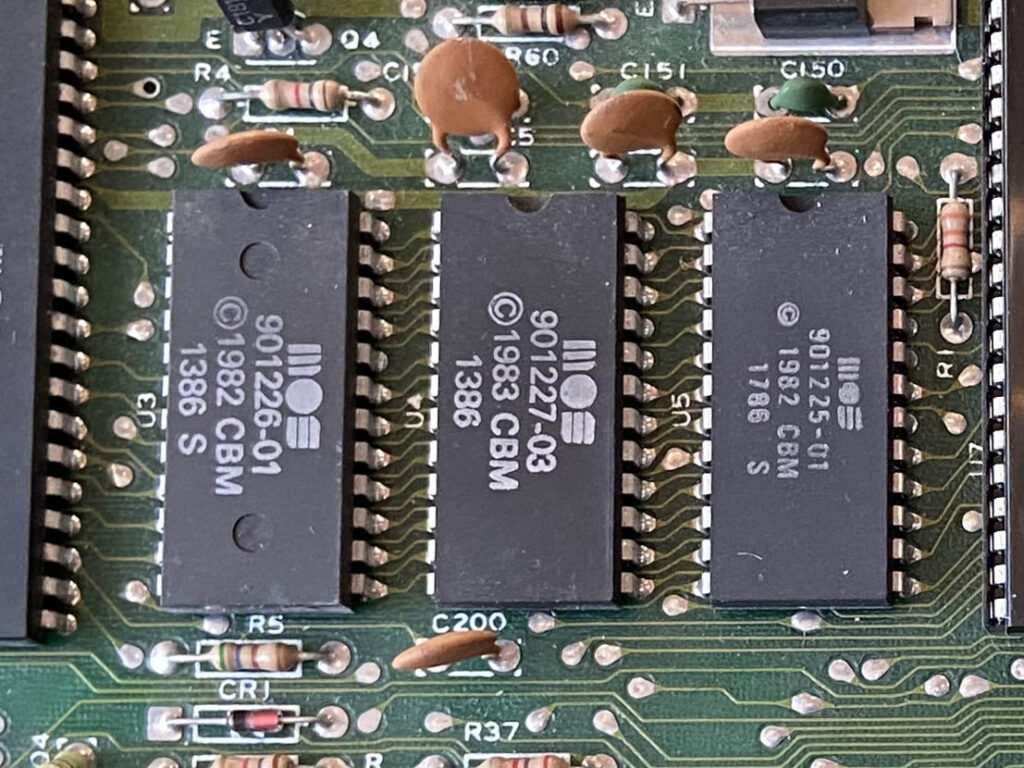

Five in a row: The four ROM chips of the Plus/4 to the left and the PLA to the right.

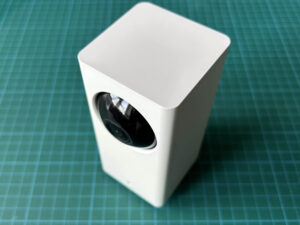

The four ROM chips of the Plus/4 are sitting all in one row, and then there is a fifth IC right next to them: the 251641-02 PLA. This PLA chip is the same for all TED based Commodore computers, the C16, the C116, and the Plus/4. In the past, I used the excellent PLA16V8 from D. Mantione as a replacement. The PLA16V8 is quick to build from cheap parts that are easily available. And for a C16 with it’s roomy case, it’s a perfectly adequate solution.

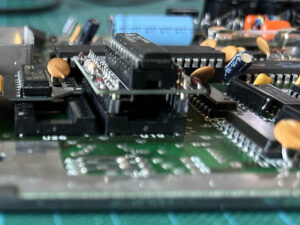

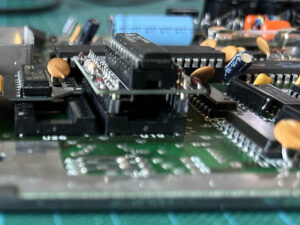

The original PLA16V18 is much too tall to fit under the keyboard of the Plus/4.

With the Plus/4, however, it’s all about space again: There are only a few millimeters between the original PLA and the keyboard above it. So while the PLA16V8 works fine on a Plus/4 motherboard, it is far too tall to fit inside the Plus/4’s case.

Continue reading →